COMPREHENSIVE APPROACH

STABLE QUALITY

HIGH PRECISION

The company of "TS Liteynoe proizvodstvo" provides a full range of services for performing turning, milling, gear cutting, slotting, drilling, balancing work, plasma cutting and heat treatment.

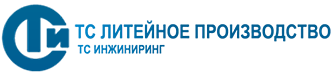

The plasma cutting:

Thermal cutting machine model "RUM 2500GP" production "PIERCE CONTROL AUTOMATION (Czech Republic-Australia) c CNC system "Burn y 10 LCD".

- The workpiece dimensions of sheet, mm: 2000x6000

- The minimum diameter cut hole: Plasma technology (source Hypertherm HRP-260XD), mm – 10 (but not less than 1.5 times the metal thickness).

- Oxy-fuel technology, mm – 15 (but not less than 1.5 times the metal thickness).

- The thickness of the metal : Plasma technology: breakthrough, mm – 0,5 – 35 from edge, mm – 0,5 – 50

- Oxy-fuel technology: the breakthrough, mm – 4 120 from edge, mm – 4 – 150.

- The surface finish of the cut and precision comparable to rough machining.

Lathe-milling sector:

Milling CNC Three machines from HAAS model VF-3, VF-4 .

- Maximum size of workpiece, mm – 1000x500x400.

- Maximum weight, kg – 500 kg.

Lathe (turning) CNC machines: HAAS SL-30 and Victor V-Turn 26

- Maximum workpiece diameter, mm – 300.

- Maximum length, mm – 550.

- Maximum weight, kg – 60.

Lathe with a vertical axis spindle CNC "HESSAP"

- Maximum size of workpiece, mm – D400, H500.

- Drive power - 80 kW

For procurement of works used band saws:

- The maximum diameter, mm – 370.

The universal lathe of the Park:

- Maximum workpiece diameter, mm -500.

- Maximum length, mm – 1000.

- Maximum weight, kg – 500 kg.

Equipment for drilling holes:

- Maximum size of workpiece, mm – 500x500x300.

- Maximum workpiece diameter, mm – 32

- Details Dimensions, mm – 600х500х400.

Slotting equipment (machine 7A420):

- The shaping cutter stroke length, mm 200.

- Maximum diameter of workpiece, mm – 500.

- Maximum length of workpiece, mm – 320.

Capabilities gear cutting equipment:

- Straight teeth: max. module 10, the maximum component diameter is 250 mm.

- Sprocket chain: the maximum diameter is 500 mm, the maximum step – 31,75, the maximum roller diameter – 19,05.

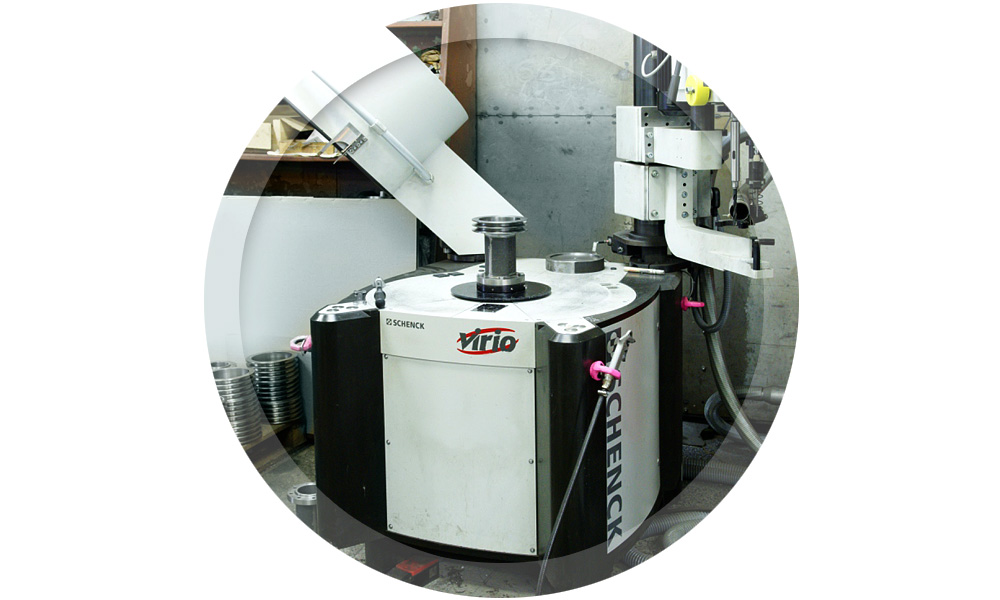

Balancing equipment:

Balancing the vertical machine Virio 100. Carried out static and dynamic balancing of rotors.

- Maximum weight, kg – 50

- The maximum size diameter, mm – 500

- Maximum height, mm –320

- Rotation speed, m/min – 600

- Drive power, kW – 4

- Precision balancing: single plane – 10-20 g∙mm for two planes – 20-40 g∙mm

In combination with lathe CNC equipment allows the manufacture of pulleys, flywheels and other high speed rotating parts.

Assembly area:

Opportunities for welding of steel structures:

- There is equipment for welding in atmosphere of protective gas (CO2)

- Welding electrodes

- Manual plasma (cutting thickness up to 8mm)

- Technological equipment for the manufacture of thin-walled spirally pipes with a thickness of 1-2 mm, diameter ø160-400 mm, max length up to 8000 mm, with sealed seam and precise geometry.

We also manufacture the augers and screw conveyors:

- The maximum dimensions of welded structures, mm – 12000x6000x1500

- The maximum product weight, kg -3000.

Possibilities for Assembly:

- Highly qualified staff has the necessary skills and mechanized equipment.

- The site is limited only by the size of the construction 30000x12000x6000 mm and lifting mechanisms of 5000 kg.

There are also opportunities for painting product dimensions 8000x6000x2000 mm by pneumatic spraying.

Thermal treatment:

Electric resistance furnace company "NAKAL". The basic direction – annealing, normalizing, quenching and tempering of steels and cast iron of various grades. Controls on stationary hardness method Rockwell and Brinell. Also a portable device for measuring the hardness.

Technological capabilities:

- The maximum temperature -1100°,

- The maximum dimensions: shaft kiln – diameter 750 mm, height 1400 mm, weight 1500 kg (one piece up to 900 kg) chamber furnace – dimensions 1150x550x500 mm, weight up to 350 kg oil quenching tank – dimensions 1000x1000x1000 mm, weight oil 1500 kg, the limit of the hardened parts 125 kg

Click on the "Get advice", enter your details and we will call you back.

We are pleased to provide information, thank you.